These are most efficient travellers that provide

Increased life

Optimum consumption

Improved Production gain

100% Improvisation :

Ring Life – 21%

Speed – 10%

Yarn Quality – 19%

Production – 10%

Traveler Life – 40%

Quick Connect

Option of Bright Finish and Black Finish

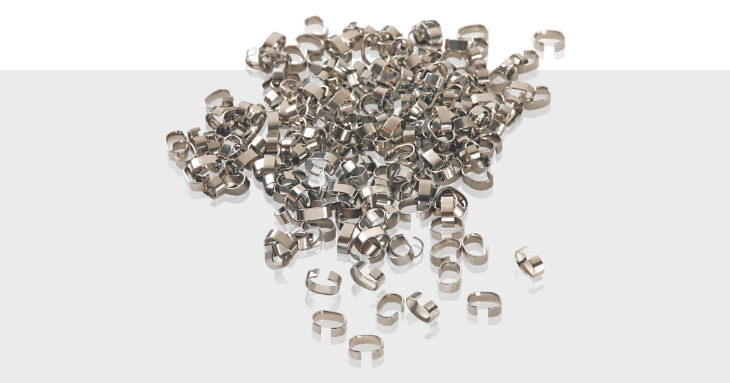

The X -axis, XL-RS travellers has been specially developed for high performances. The enrichment components are present throughout the entire traveller section and do generate their effect even when the surface is affected. XL-RS can used for the ring running-in, normal operation and covers the entire finer and yarn count range.

Quick Connect

The X-Axis, XL-CS travellers has a special coating and is applied with a special process. It lowers friction values in the yarn passage and prevents fibre damages. XL-CS offers optimum resistance to corrosion

Quick Connect

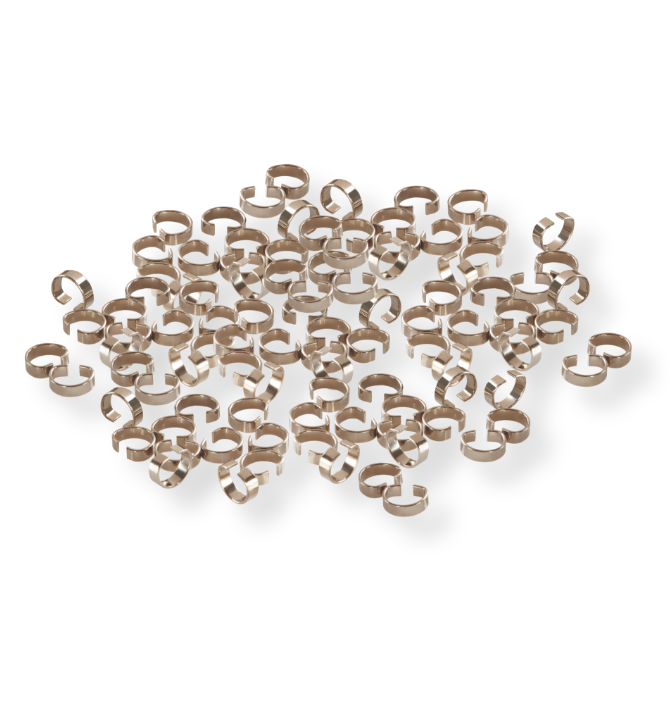

The X-Axis Xendow Travellers offers lowest friction value reducing Yarn breakages. Special coating gives longer life than regular travellers in conventional spinning and compact spinning.

Quick Connect

The X-axis Xgen Travellers have fine and uniform micro structure, practically no friction surface treatment. Improved wear resistance, offers excellent longest life and Best Quality. It is a perfect blend of top-of-the-line metallurgy and latest technology.

Available in RS and CS finish.

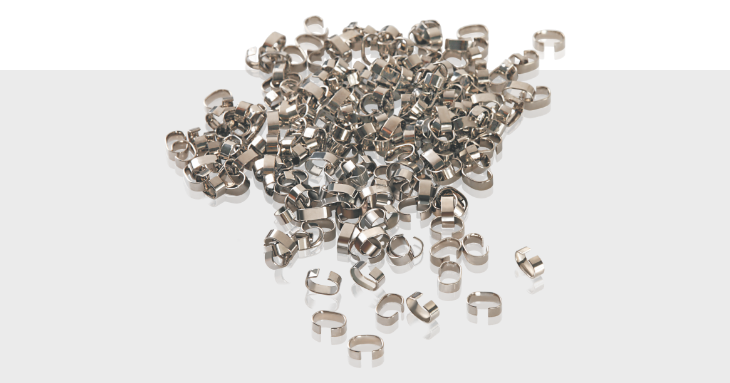

One of the most advanced range of Travelers manufactured with latest technology; it offers largest number of Travelers suited for any type and on any make of machine in the world. It spins, Super fine or coarse, with best end results. It performs to utmost Output, Consistency and Longevity. Performing efficiently at spinning units all across.

Quick Connect

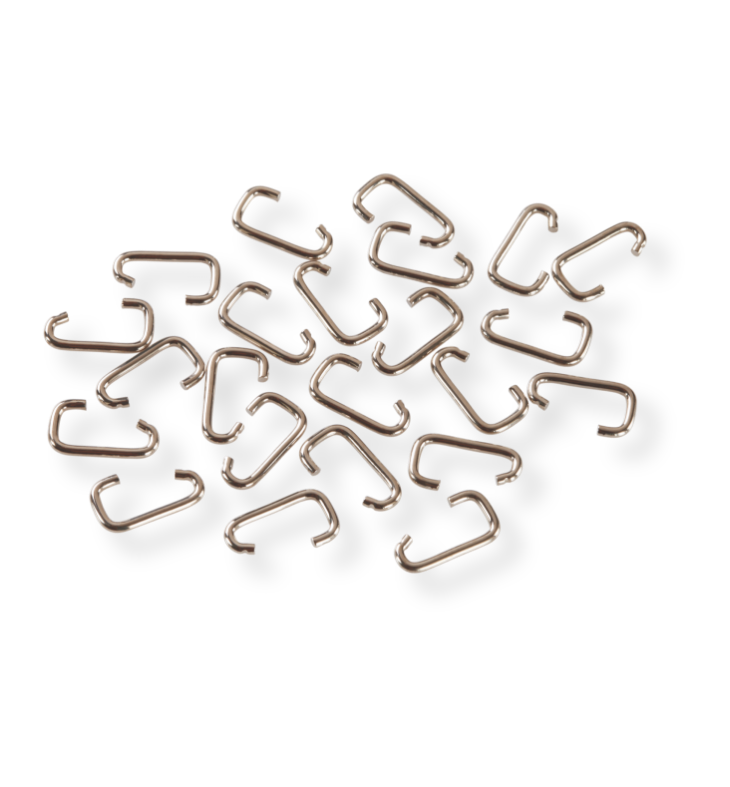

J Traveller of Steel

XL-CS, XL-RS, XL-PS

Traveller Designations

The Designation of X-axis J Travellers are based on international standards

J 9.1 r Standard No. 28 / ISO No. 40 XLCS

J 11.1 r Standard No. 24 / ISO No. 90 XLRS

| Explanation | ||

| Traveller Shape | J | J |

| Ring Height | 9.1 | 11.1 |

| Wire Profile | Standard | Standard |

| Material | Steel | Steel |

| Traveller No. | 28 | 24 |

| ISO No. | 40 | 90 |

| Traveller Finish | XLCS | XLRS |