About the X-axis

With over 60 years of experience in spinning ring manufacturing, The X-Axis is acknowledged as the leading global supplier of spinning rings and ring travellers from India. The sheer dependence of Ring Spinning machine on Spinning Rings and Ring Travellers makes them the most influencing components for spinning machine’s productivity. The Rings & Travellers by The X-Axis are an extraction of companies indigenous strength, which comes from company’s immense global market experience. The X-Axis follows the best International standards of manufacturing.

The X-Axis has varied product range to meet every kind of Ring Spinning requirement. The X-Axis is among the top brands in the world having wide global presence and acceptance.

Significance of Rings & Travellers in

Ring spinning

Our in-house studies indicate that, Rings has a direct influence on the Spinning output, consistency and longevity of spinning, as well as weaving, knitting, dyeing and finishing.

Spinning Rings indirect advantage is that they provide a perfectly engineered path, while Travellers provide twist to the yarn and then helps in winding the yarn.

Its direct significance can be seen in perfect Cop building.

As the drafted fiber strand passes through different physical phenomenon here, which reflects in formation of the final Yarn. It is here that the quality of ring compensates the Torsional Force on fiber strand without influencing the twisting, winding and spinning tension, that contributes in producing international class Yarn and globally accepted perfect Cop after Cop after Cop.

Reliable & Consistent Output

The challenge of quality is not only in bettering output but to bring consistency i.e. producing quality without (significant) variation throughout its operational life. This helps spinners in producing good quality Yarn.

Optimises spinning machine efficiency

Its molecular structure of processed steel outruns in quality and length of life that helps to optimise the spinning machine efficiency. Thus, it gives longevity to Spinning, Weaving, Knitting, Dying and Finishing.

These suggest that the quality and selection of Spinning Rings should be judged only in the light of its Output, Consistency and Longevity

With NEXT spinners across the globe are empowered to unlock gen-next spinning quality. Spinners across the world, face similar challenges. Crucial among those are :

- How does a spinner generate desired fineness in yarn without replacing spinning machine?

- How to spin at high speeds and yet have reduced yarn hairiness?

- How to control effects on twist variation during manufacturing of yarn ?

- How to optimise CV of yarn count during the ring spinning process?

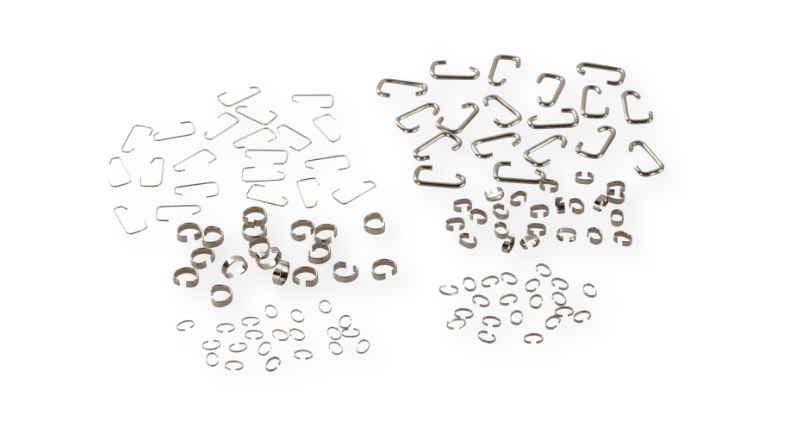

The spinning rings and ring travellers from The X-Axis enhance the critical quality parameters that spinners need, they are : Tensile Strength, Surface hardness, Fatigue Strength, Wear resistance, Friction reduction, Corrosion resistance.

Rimtex Group

The Rimtex Group of industries is among the foremost manufacturers in the world serving needs of Textile and allied industries. The group has a firm footing in innovation and excellence which makes them a leader with a wide global reach in over 50 countries. The group has a collective experience of over 6 decades in the manufacturing sector.